When it comes to office design and installation, metal trunking systems play a crucial role in the way electrical and data cabling is managed. Metal trunking provides a safe and organised means to distribute these services, ensuring that everything from power to communication lines is efficiently routed and protected and the risk of interference minimised. Protection includes keeping cables safe from dust, damage and humidity. A further important point to note is that if the right choice of trunking is made, layout planned for future use, then trunking can also be scalable and adaptable. While there are various types of metal trunking systems, today we’ll focus on two of the main options required in office environments: In screed trunking and flush floor trunking.

In screed trunking: The heart of efficient trunking

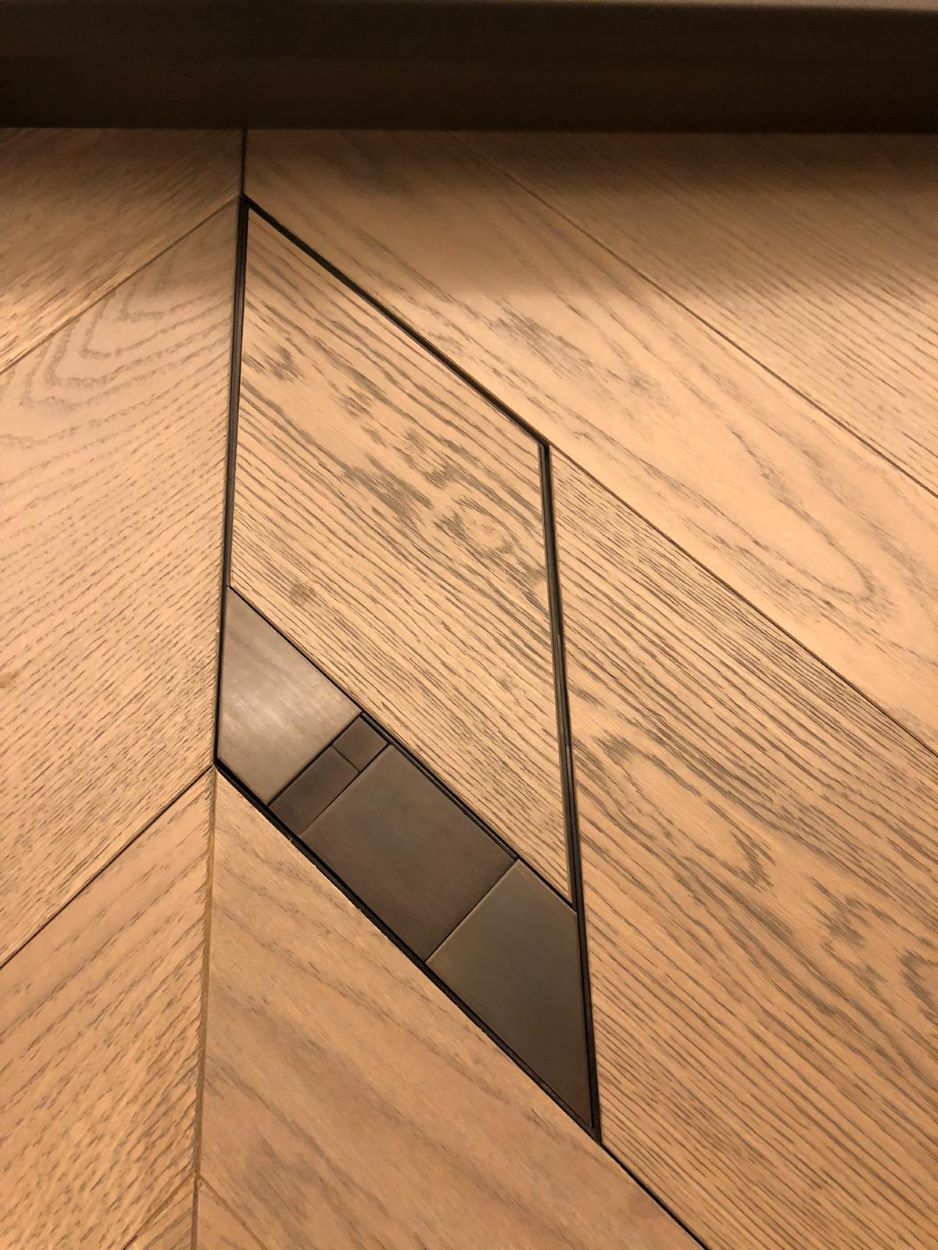

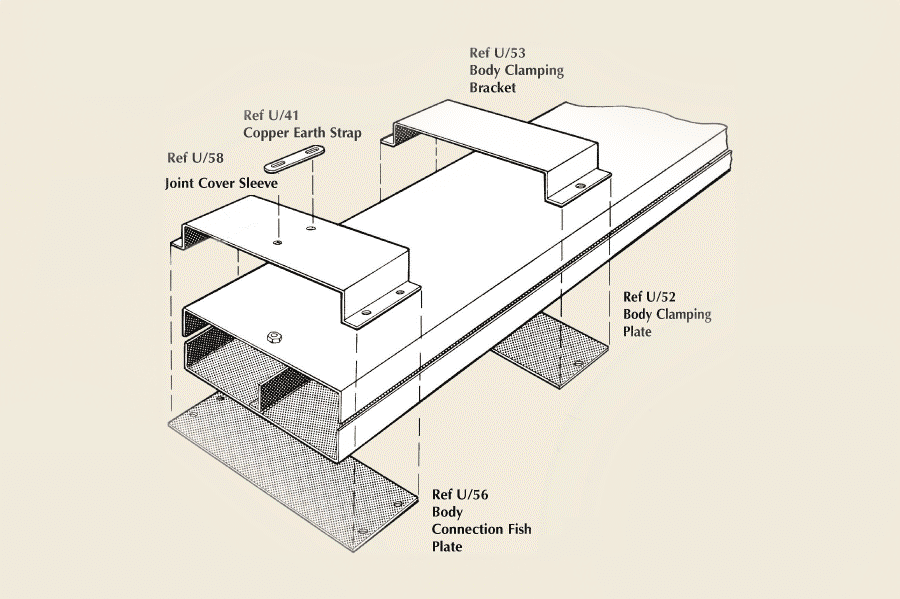

The in screed system is often the more interesting choice for designers and installation professionals, particularly in more complex projects. Typically used with the 700 Series and Minima floor boxes, in screed systems involve burying the trunking within the floor itself. Junction boxes can also be integrated into this trunking system. This not only provides a clean and neat finish but also ensures that cables and wiring are securely housed beneath a solid surface.

In screed systems are favoured in environments where durability and a high-quality finish are essential. They offer an advanced solution where office aesthetics and cable management take priority. The ability to bury trunking within the screed floor makes it especially appealing for modern office layouts that require a minimalist design without compromising on functionality. These are most likely to be new build projects that tend to use solid or concrete floors on multiple levels.

Flush floor trunking: An adaptable and simple solution

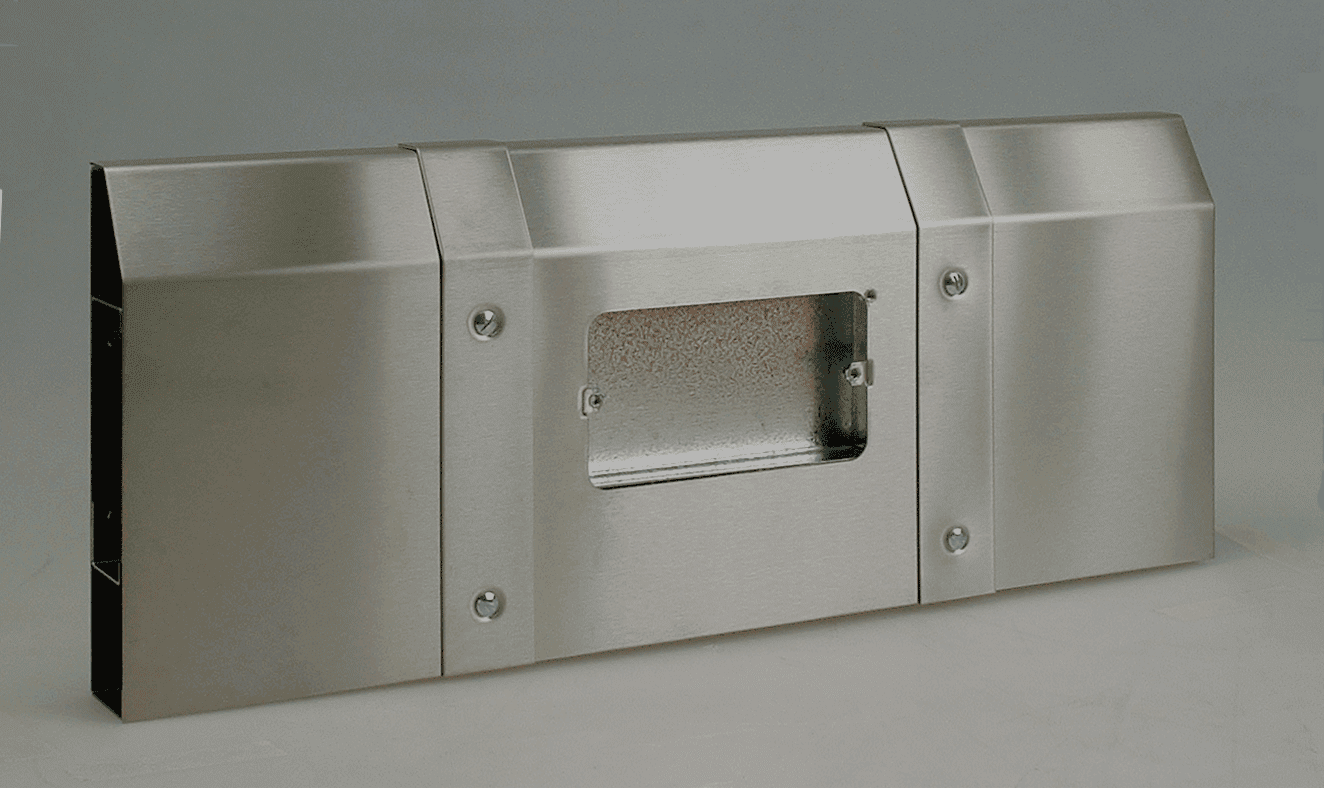

The flush floor system is commonly used in offices where the final floor height is minimal, typically no thicker than 6mm. This can include applications such as carpet tiles or other thin finishes. While this system can be used as a stand-alone system in specific situations, it’s usually installed as part of an integrated solution with the 2000 Series (see image) and 500 Series floor boxes. These systems are designed to be discreet and flush with the floor finish level, which is a preferred aesthetic for many office spaces.

The flush floor system is also very adaptable and represents an excellent opportunity to future-proof your office layout and operation. If re-organisations and movement of work stations are a likely occurrence, then floor box positions will need to change. The trunking lid containing Cableduct’s 2000 or 500 floor box can be unscrewed and easily moved up or down the trunking run to a new position.

However, flush floor systems are generally not at the forefront of trunking design discussions. They’re a simpler, less noticeable solution that doesn’t tend to require as much attention in terms of complexity or design. A major part of this system’s appeal lies in its ability to blend seamlessly into the floor, making it a good choice when you want minimal disruption to the office’s appearance.

The right trunking for your space

Choosing the right trunking system for your office or facility depends largely on the unique requirements of the space, including design, budget, and the practicality of installation. Whether it’s a more robust buried in screed system or a discreet flush floor system, understanding the options available and their respective advantages will help you make an informed decision. Both of the metal trunking systems that we have explored in more detail are typically seen as among the more elegant and longer-lasting solutions available.

If you’d like to find out more about trunking systems from Cableduct, contact us today. You can call us on 020 8683 1126 or via our online contact form.