Why retrofit floor boxes are an essential tool in the specifier and contractor ‘tool-box’

November 7, 2025 | Product News

Retrofit floor boxes are an invaluable part of any floor box range as these provide specifiers and contractors with more options when considering project management challenges such as: timing and co-ordinating the installation of flooring, floor boxes and electrical services; choosing type of floor covering; and deciding whether you can keep an existing floor covering or will have to replace it.

Having this retrofit option available puts project decision-makers in a stronger position and gives them more confidence that the project can be completed on time and that they will be able to work around such challenges. This makes access to specialist retrofit floor boxes an essential tool in the specifier and contractor ‘tool-box’.

How do retrofit and standard assembly floor boxes differ?

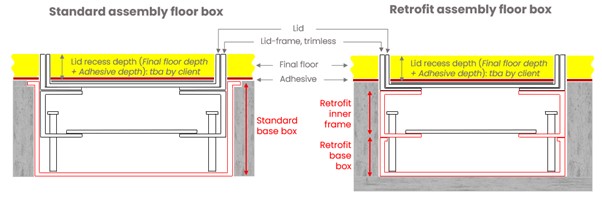

For the majority of projects, standard assembly floor boxes are used and have the following main characteristics:

- The base box must be installed before the final floor covering is installed

- This is because the base box is larger than the lid-frame and has fixing flanges which are fixed to the top of a secure fixing point, i.e. screed. These will end up underneath the final floor covering when it is fitted

- The lid and lid-frame is fitted on top of the galvanised frame, which sits inside the base box

- If the floor box has been supplied complete, then the final floor covering is fitted tight up against the side of the lid-frame, covering the fixing flange

- However, if the floor box has been supplied in two parts, then the galvanised inner frame, which has the same dimensions as the lid and frame, will be supplied sooner. This can be temporarily elevated up above the height of the base box to act as a temporary template for the lid up to which the final floor can be laid

- Standard assembly floor boxes can be supplied in two parts to help with lead-times, broken down as follows: first fix items (base box and outlet plates) supplied in days; and second fix items (lid) within weeks.

However, in certain circumstances, specialist retrofit assembly floor boxes are required, which have the following benefits:

- If you intend to keep the existing flooring or need to install a floor box after a new floor covering has been fitted, then a retrofit assembly floor box is required

- This is because the lid-frame is the largest dimension and a retrofit base box does not have a fixing flange. This allows the floor box to be fitted into a hole cut in the floor retrospectively

- This also means that the method of support is different for a retrofit floor box as it must be supported under the base box or according to prevailing site conditions

- Additionally, if you want a poured finish, such as micro cement, resin, terrazzo or polished screed, then a retrofit floor box is required as it mitigates the risk of poured material penetrating the floor box

- Retrofit floor boxes are supplied complete as one unit

Retrofit 700 Series floor box

We explore the benefits of specialist retrofit boxes in more detail below, particularly for installations into existing flooring where they are used most often.

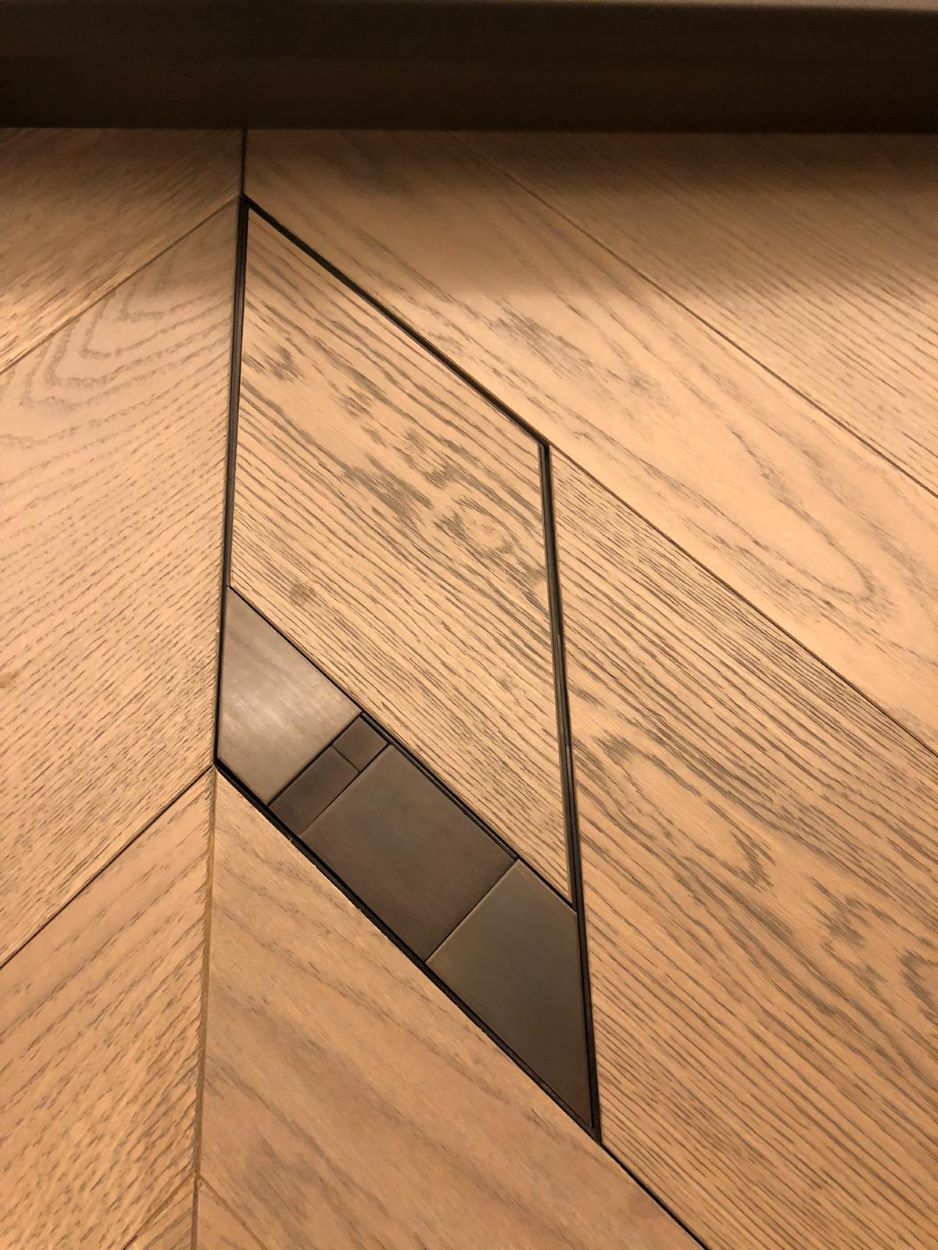

Installing a retrofit floor box into an existing floor

When modernising an older building, one of the significant challenges is implementing effective cable management without undertaking extensive renovations. Retrofitting floor boxes is often an ideal solution for updating power, data, and AV connections in existing flooring and structures. This approach allows for the installation of modern connectivity solutions while preserving the building’s structural integrity, original floor covering and aesthetic appeal.

In this section, we’ll explore various methods, considerations, and best practices for integrating floor boxes into flooring within such buildings that weren’t originally designed with these systems in mind. Whether you’re working on a Grade II listed property, a mid-century office building, or a recently acquired commercial space, these solutions will help you implement effective cable management systems with minimal disruption.

Understanding the retrofitting challenge

Before looking into specific retrofitting techniques, it’s important to understand the unique challenges presented by existing buildings. Some common challenges include:

- Limited access to underfloor areas

- Presence of existing floor finishes that need preservation

- Variations in floor construction (solid concrete, raised, suspended, etc.)

- Heritage considerations in listed buildings

- Need to minimise disruption to ongoing operations

Unlike new construction where cable management infrastructure can be planned from the beginning, retrofit installations require creative solutions that work within existing constraints.

Assessing the space for your floor box installation

A thorough assessment of your building is essential before selecting the appropriate floor box solution and considerations may include.

Service requirements planning

Careful planning is an important part of any retrofitting project. To ensure the smoothest installation possible, document the types and quantities of services needed.

- Power requirements

- Data and telecommunications needs

- Audio-visual connections

- Future expansion considerations

A detailed survey helps determine the most appropriate floor box type and size for your specific requirements.

Cable routing considerations

Any void beneath the flooring provides natural space for cable routing. However, when retrofitting, consider the following points:

- Method of supporting retrofit floor box

- Existing services that may already occupy this space

- Fire barriers that must remain intact

- Structural elements that cannot be disturbed

Installing a retrofit floor box after a new floor covering has been fitted

Where new floor coverings are being installed in new or old buildings, most cable management infrastructure can be planned from the beginning. However, for all building projects, working within tight time constraints and co-ordinating different trades are key success factors and the retrofit floor box gives another option that can help project managers keep their project on track.

There can be many reasons why the floor covering has to be fitted before a standard assembly floor box can be installed and, where this is unavoidable, a retrofit floor box can be a good solution. This may not have been the plan originally but circumstances change on site and project managers need alternative solutions that help them keep their project on track.

Selecting a floor box manufacturer with a range that includes both standard and retrofit assembly floor boxes keeps your options open and maximises your chance of success with completing your project on time and as per specification.

An important consideration for installing a retrofit floor box is planning ahead for how it will be supported. The main point of support is under the base box as there are no fixing flanges on the side. While you can plan for most variations in depth ahead of the installation, you will most likely still want to fine-tune the height of the lid to make it perfectly flush with the floor covering. This can be achieved using the height-adjustable inner frame at the time of the final installation.

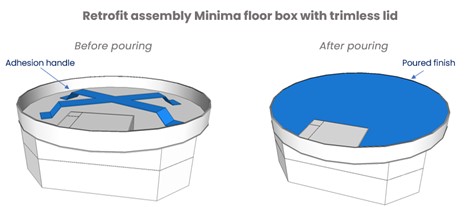

Installing a retrofit floor box into a new floor with a poured finish, such as micro cement, resin, terrazzo or polished screed

This specialist floor finish must be managed differently as the poured material can penetrate a standard assembly floor box and damage the internal components and workings.

Floor boxes with retrofit assembly should be used on all such installations as they are supplied as a complete unit and, with a few simple measures, can prevent ingress of poured material. There is also the option to have a concrete adhesion handle in the lid to help key the screed into the lid whilst it is curing:

- Joins between parts of the floor box may give some access to poured material and so we recommend that the following joins should be taped between base box & inner frame and inner frame & lid frame

- If the retrofit floor box is installed before the flooring is poured, the lid should remain fitted inside the lid frame to ensure the weight and pressure from the poured material and pouring process does not cause the lid frame to bend in and prevent smooth and easy movement of the lid in future

- If the finish will be poured before installing the floor box, then we would recommend building a mould or void former to keep clear a hole with the exact measurements required by the retrofit floor box, as per manufacturer installation guidelines.

- It is also important to note that the area in and around a retrofit floor box being used with a poured finish is polished or finished by hand, not by machine, to protect the floor box lid.

As you can see, specialist retrofit assembly floor boxes bring many benefits and successful installation is possible with a little forward planning and some care and attention. If you’re planning to fit retrofit floor boxes and you’d like to find out more about the Cableduct floor box range, get in touch today. For more information about any of our products or services call 020 8683 1126 or send us a message online and we’ll get back to you as soon as possible.